Historically, double-station radial-axial hydraulic ring rolling mills and multi-mandrel ring rolling mills for closed-die rolling have already been built. Both types of machines offer high productivity but use two different rolling technologies.

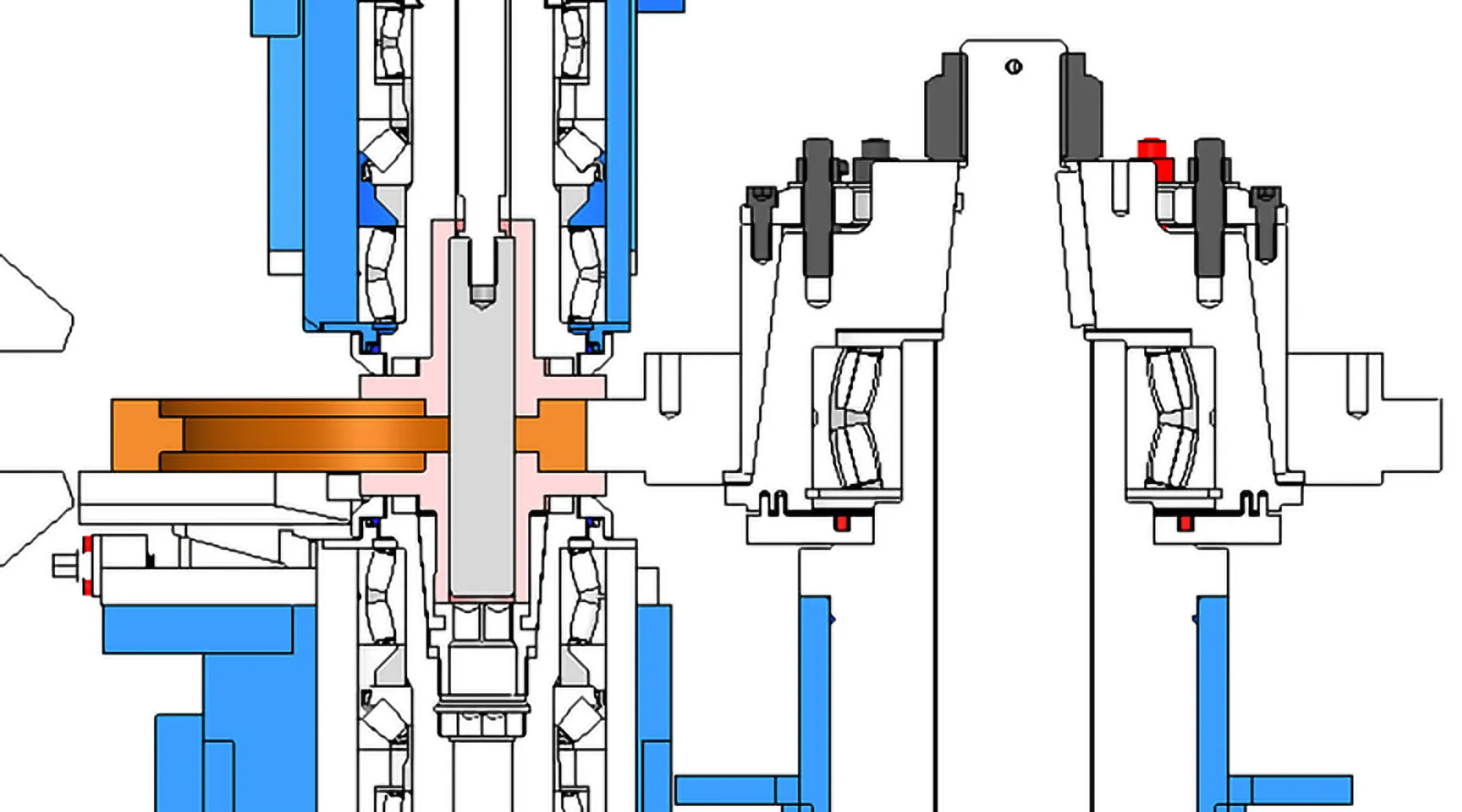

Based on its experience with multi-mandrel and radial-axial ring rolling mills, ECAI has designed a new machine that combines the main advantages of both these types of machines.

ECAI is constantly improving its design in order to always guarantee an innovating product.

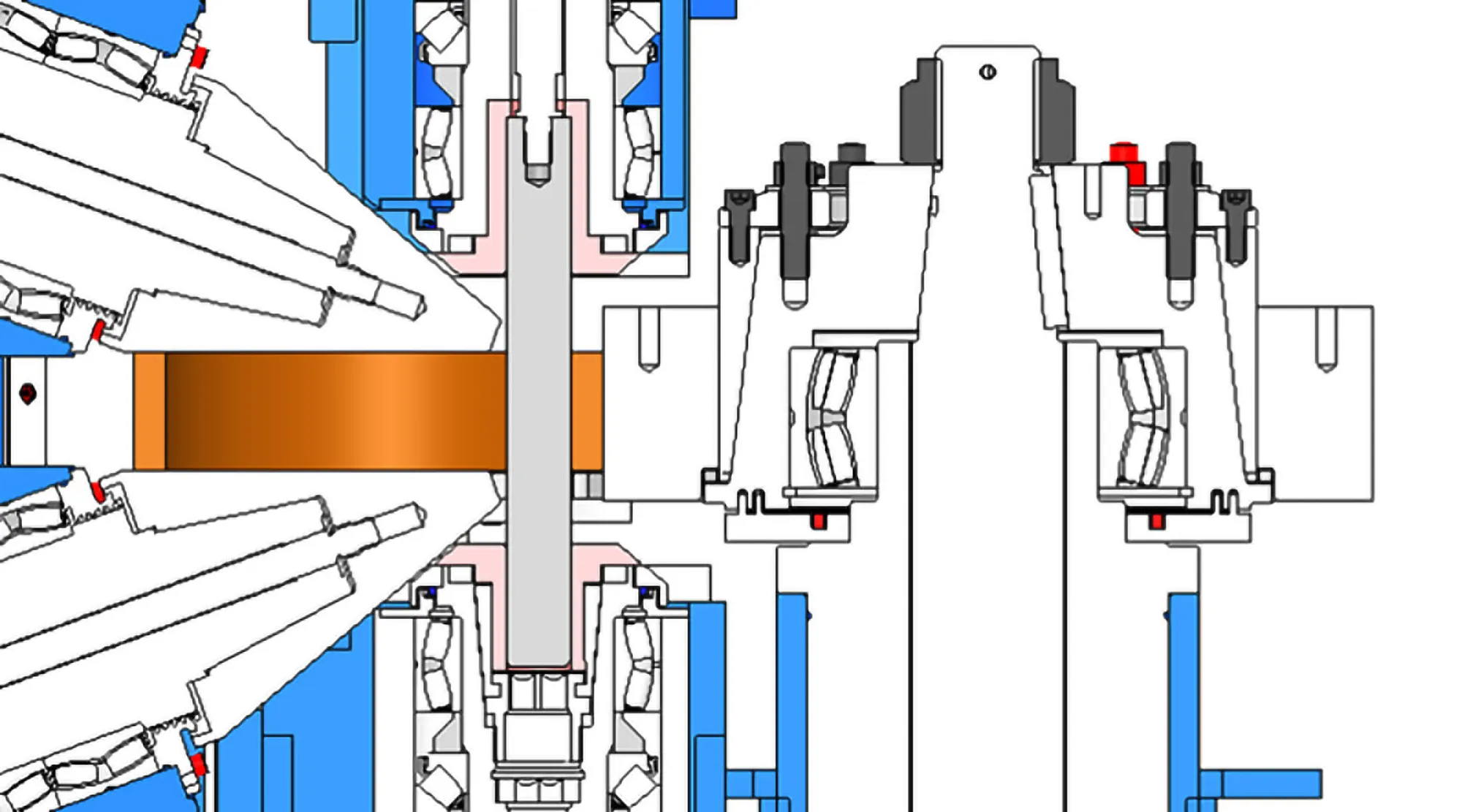

The Omega® ring rolling mill is suitable for the production of rings by radial-axial rolling as well as by closed-die ring rolling.

This very compact machine has been designed to be installed on a very simple and small foundation.

It can be supplied with one or two stations. In the latter case, productivity is very high, as while rolling is taking place on one station, the other station is being unloaded and loaded.

The Omega® can be integrated into a fully automated line for high productivity requirements.

As with the other machines in our range, the radial and axial stands and centring arms are operated by electromechanical controls, unlike traditional rolling mills which use hydraulic cylinders, thus also eliminating all maintenance and environmental issues associated with hydraulics.

Omega® crown rolling mills are cold and hot tested in our workshop before delivery to ensure short installation and commissioning times in the customer's workshop and a quick start to production.

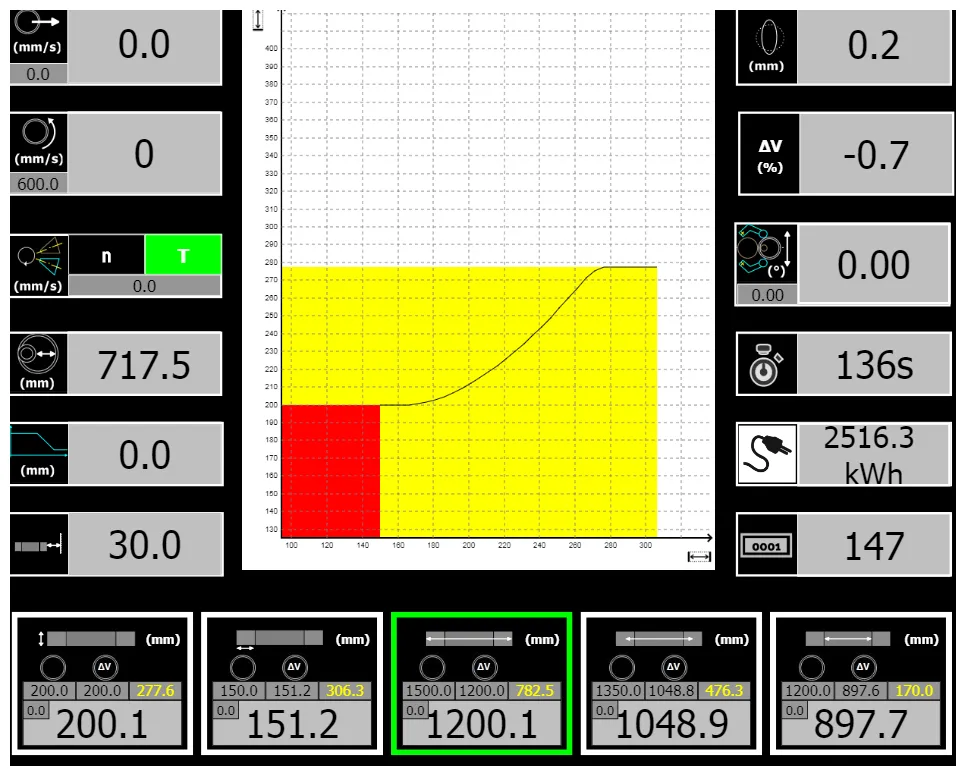

Our RingLab® control system is highly intuitive and uses graphic symbols rather than text.

In most cases, only the dimensions of the blank and the final part need to be entered by the operator, with the system automatically calculating all relevant parameters.

RingLab® is completely open to the outside world via CSV (Excel) files or its open SQL database, allowing for exchanges with a higher level.

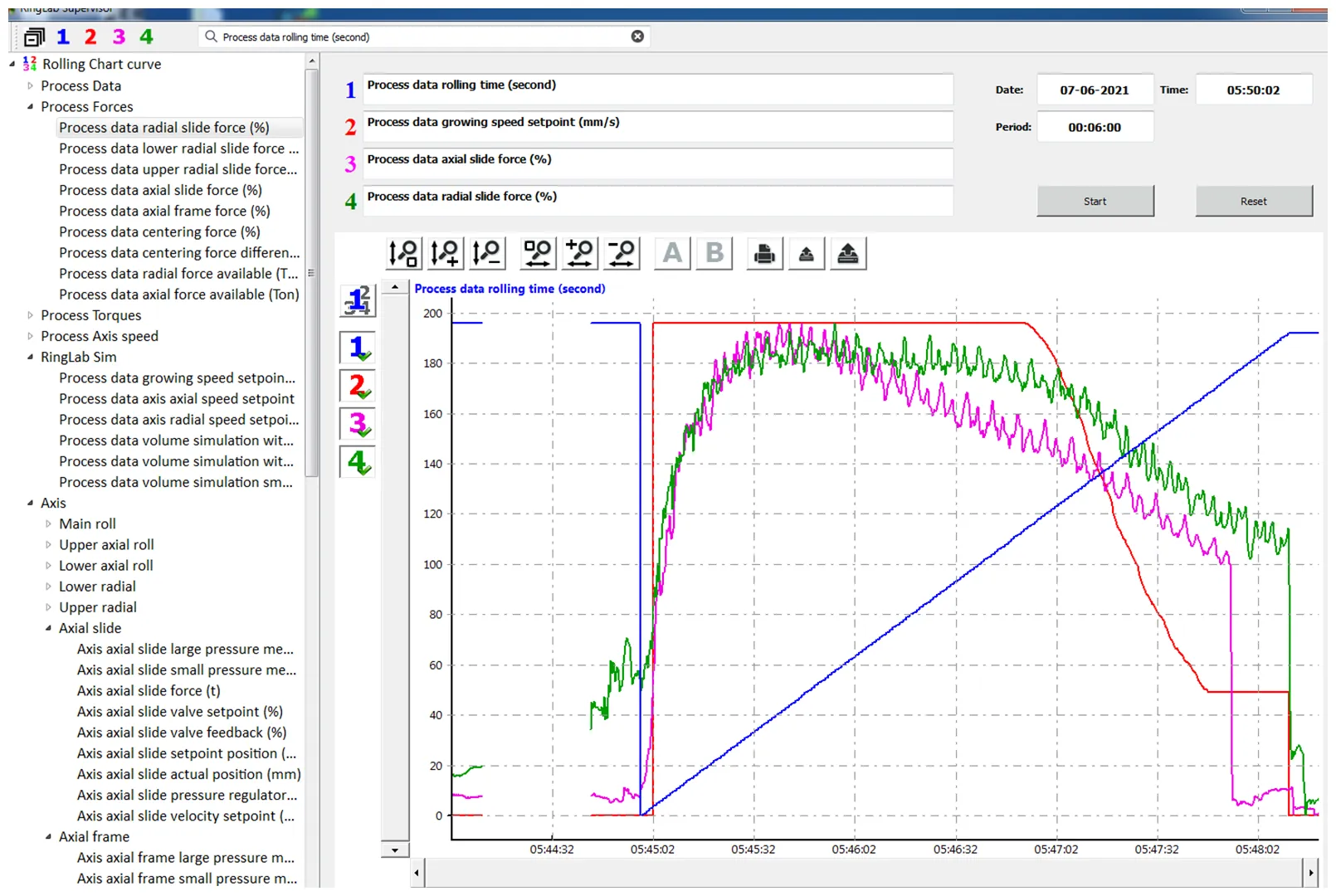

Thanks to RingLab® Supervisor, it is possible to monitor the recording of all rolling data (more than 400 parameters). This can be done directly on the machine or on a computer connected to the machine.

Our RingLab® control system is highly intuitive and uses graphic symbols rather than text.

In most cases, only the dimensions of the blank and the final part need to be entered by the operator, with the system automatically calculating all relevant parameters.

RingLab® is completely open to the outside world via CSV (Excel) files or its open SQL database, allowing for exchanges with a higher level.